The name is bulletproof glass, however, it is not mandatory that it “only consists of glass”. Bulletproof glass can also consist of transparent plastic materials such as polycarbonate or acrylic. Or in an ideal case it can consist of a combination of glass and plastic material, because this material mix stops projectiles especially effective.

At this place we will now explain the different types of bulletproof glazings and we will explain the applications for which they are especially qualified.

The glass buildup of bulletproof glass is differentiated in symmetrical and asymmetrical. Symmetrical bullet proof glass is built identical on both sides and therefore it protects evenly against bullets from both sides. Logical. Bulletproof glass panes are to a large extend designed asymmetrical, because projectiles can with this design be stopped more effective, which means with less material expenditure.

Therefore bullet proof panes with an asymmetrical design are only bulletproof on one side, namely on the attack side. Adherence to the respective installation direction is required. The attack side of the glazing points to the threat and the so-called defense side represents the protected side.

| bulletproof glass symmetrical | bulletproof glass asymmetrical | |

|---|---|---|

| Benefit | bulletproof from both sides | slightly thinner and lighter |

| Disadvantage | thicker and heavier than asymmetrical | Adherence to the installation direction is required |

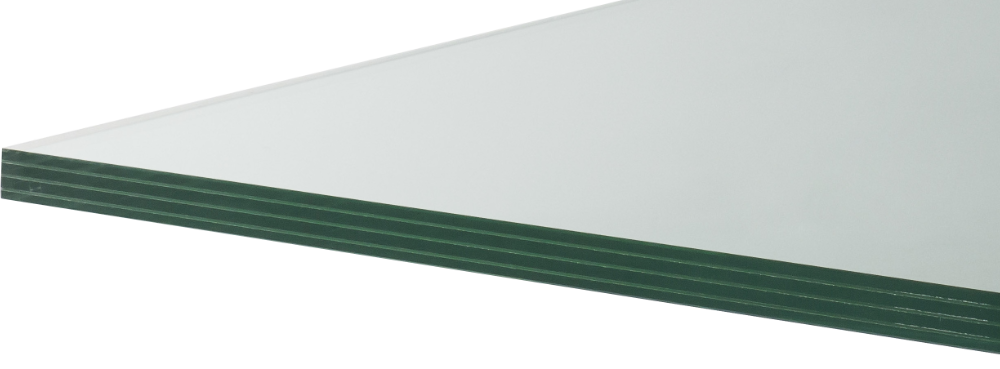

Glass and polycarbonate: The ideal combination for bulletproof glass if it is important to save a lot of weight and additionally to build with thin panes. In addition, these glass panes are crystal glass and they do not have the otherwise common green tint. This is by far the most superior of all design principles for bulletproof glass. The windows can be easily opened due to the low weight. It is outstandingly qualified for the protection of mansions as well as public buildings. Also, because these panes offer additionally a high burglary protection in contrast to other bulletproof glass panes. SILATEC is for decades the worldwide leading manufacturer for bulletproof glass polycarbonate glazings.

| Benefit | thin, light weight, transparent, high burglary protection |

| Disadvantage | more laborious to produce than conventional laminated armored glass |

This is where several glass panes are laminated with a thin foil until a thick glass packet is generated.

The thicker this glass pane the larger is the protective effect against projectiles. The disadvantage of this design principle is obvious: The thicker the bulletproof pane is the heavier it is. A high glass weight is especially disadvantageous for windows and doors, because the fixtures can only absorb a limited weight. An additional disadvantage: The glass has more green tint if it is thicker. The view through the pane appears more green with an increasing glass thickness. The burglary protection of these glass panes is low. Large holes can be knocked-in in less than one minute even in 100 mm (4”) thick armored glass, for example with a sledgehammer.

Does bulletproof glass exists that consist practically not of glass? Yes. Such bulletproof panes consist only of transparent plastic materials. Polycarbonate and PMMA, which is also known as acryl glass, is used among others. These bulletproof panes are very light weight and they are therefore installed, among others, in special vehicles or construction machines. A disadvantage is that these pure plastic material solution are practically only providing protection against handguns. These bulletproof special solutions are practically not used in buildings, especially not in the outside areas.

| Benefit | production is normally more cost effective |

| Disadvantage | heavy, thick, green tint, normally little burglary protection |

| Benefit | very light weight |

| Disadvantage | hardly suitable for buildings in the outside area, protects normally only against handguns |

SILATEC ShooteQ

Everything about the especially lightweight and thin bulletproof glass