The designations in DIN EN 356 can be confusing. We are pleased to explain them: Five low protection classes exist (P1A to P5A glass) and three high protection classes exist (P6B to P8B glass). Safety burglary protection is only provided by the safety glazing of the resistance classes P6B, P7B and P8B.

However, burglary resisting glass (P6B, P7B, P8B glazing) will be attacked significantly more severe: with an ax and brute force.

The five low classifications of P1A glass to P5A glass mean that throwing, for example, a rock at the pane does not destroy the pane. However, these safety glass panes do not provide real burglary protection. Therefore, the designation is only “through throw resisting glazing”.

A distinction with the three high resistance classes P6B glass, P7B glass and P8B glass is only awarded for such safety glazings that provide effective burglary protection. Burglary resisting glass is the correct designation; and the P8B glass provides the highest burglary protection. The designation “attack-proof glazing” is also used in individual cases.

The safety difference between a through throw resisting glazing (glass of the resistance classes P1A, P2A, P3A, P4A or P5A) and burglary resisting glass (P6B, P7B or P8B glazing) is extreme. The largest difference is between P5A glass and P6B glass: They can be compared in the same manner as apples and oranges - namely not at all.

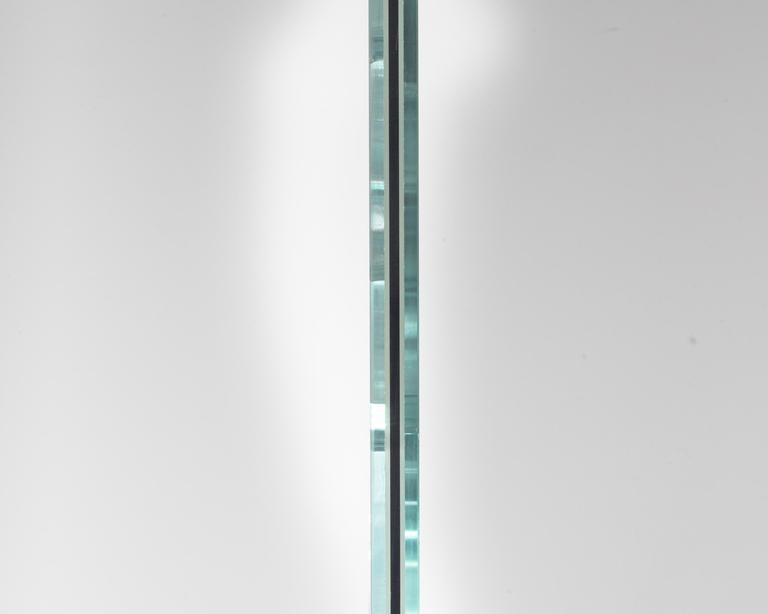

However, it gets even better. Because SILATEC glass consists of very different layers in stark contrast to conventional P6B, P7B and P8B glass. With different thicknesses. And a material mix made of highly transparent and extremely impact resisting materials. This is how we optimally utilize the different mechanical characteristics. This is the reason why burglary resisting glazings by SILATEC are significantly more resistant against attacks. What you see in our video about this subject is not a trick. But our P6B pane. A wall of glass.

Burglary resisting windows are tested in accordance with EN 1627.

The problem is: The glass will not be attacked during the burglary test!Hard to believe but true.

The standard only specifies minimum requirements for the glass resistance class, however, this does not provide enough resistance against a burglar. To say it clearly: The glass pane provides less resistance than the window frame!

For clarification:

A burglary resisting window as per EN 1627 and resistance class RC3 will be attacked with defined tools by the “average offender” and must resist 5 minutes. The glass pane will not be attacked. Only min. P5A glass is requested. The video shows what a P5A glazing withstands in practical use: There is only a large hole after a few hits.

Our recommendation: The glass pane must resist the culprit approximately as long as the window frame.

| Burglary resisting windows Resistance class | Burglary protection approx. | Glass recommendation |

|---|---|---|

| RC1 | – | – |

| RC2 | Amateur culprit approx. 3 minutes | min. P6B |

| RC3 | Average offender approx. 5 minutes | min. P6B |

| RC4 | Experienced culprit approx. 10 minutes | min. P6B |

| RC5 | Very experienced culprit approx. 15 minutes | min. P6B |

| RC6 | Very experienced culprit approx. 20 minutes | min. P6B |

This is where you will get all the information about P6B glass

P6B glass

This is where you will get all the information about P7B glass

P7B glass

This is where you will get all the information about P8B glass

P8B glass

This is where you will get all the information about P2A glass

P2A glass

This is where you will get all the information about P4A glass

P4A glass

This is where you will get all the information about P5A glass

P5A glass

We find this often in practical use: P4A glazings or P5A glazings are offered as burglary resisting glazing. This is definitely wrong. Because burglary resisting glass must at least be in accordance with the resistance class P6B. Or P7B. P8B would be best, it is the glazing with the highest burglary protection. The classification EH1, EH2, EH3 (VdS damage prevention) represent even more safety and burglary protection.

You are protected when using burglarproof glass by SILATEC. Protected as in a castle. But you are also enjoying an ambiance with plenty of light, because our breakthrough resisting glazing represents a wall, which is one hundred percent transparent. In addition, it includes a one hundred percent UV filter, which also protects your works of art or valuable carpets against fading. Nothing can penetrate - only the visible, completely unfiltered sun light.

Or you may select normal armored glass. It is heavy. It is thick. It is green. And by far not as safe and steadfast as burglarproof glass by SILATEC.

The design of P4A glass is surprisingly simple. Two glass panes and a very thin plastic foil in the middle. That’s it. The foil keeps the broken glass pieces together and prevents injuries. But burglary protection? No. Not with P4A glass.

Very simple: Burglary protection is only provided by P6B, P7B and P8B glass. The classifications P1A, P2A, P3A, P4A and P5A have no burglary protection. P6B to P8B glass is installed to provide no burglary opportunity for the culprits for as long as possible, for example, in mansions, embassies or display windows. In contrast, P1A to P5A glass is used as roof glazing or in staircase railings.